The Facts About Extrusion Of Plastics Uncovered

Wiki Article

Unknown Facts About Plastic Extrusion Profiles

Table of ContentsAll About Custom Plastic ExtrusionsLittle Known Facts About Plastic Extrusion Manufacturers.The 5-Minute Rule for Extrusion Of PlasticsWhat Does Extruded Plastic Profiles Mean?Plastic Extruded Profiles Fundamentals Explained

At Vip, we have years of experience manufacturing hundreds of special personalized plastic extrusions in nearly every shape, dimension, as well as shade you can imagine - https://href.li/?https://www.kellerplastics.com/. Our specialized depends on making plastic profiles particularly for a certain application. You inform us what you need and also we will certainly make it, meeting the greatest top quality requirements.From pre-prototype to post-production, ACE has the capability and innovation to do it all. We serve huge and small business in markets varying from automobile to medical, with difficult product needs to limited tolerances in America, copyright, Mexico, and Europe. Regardless of where you are or what industry you represent, you can depend on ACE for personalized service and also client fulfillment.

That implies fast quotation solution or product referral is just a phone call away. Your concerns are constantly addressed immediately by our skilled solution staff, and also you receive the assistance you need with no delays or confusion.

8 Easy Facts About Custom Plastic Extrusion Manufacturers Explained

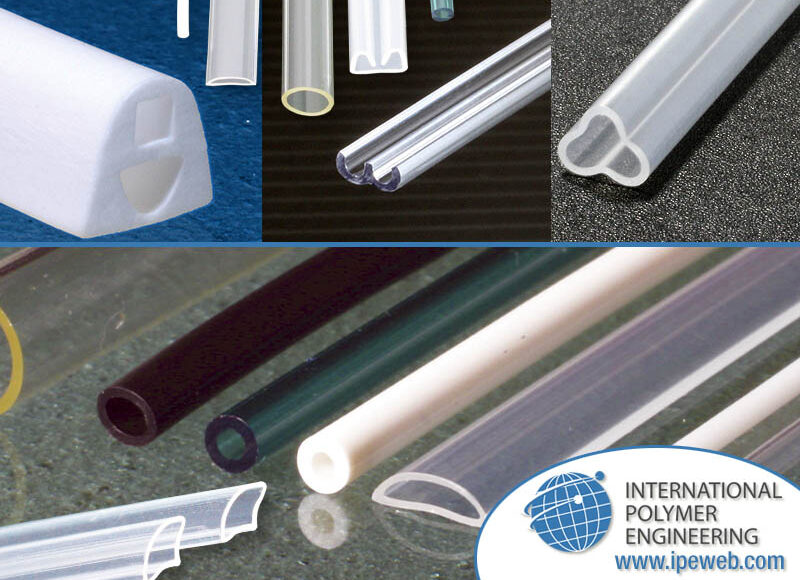

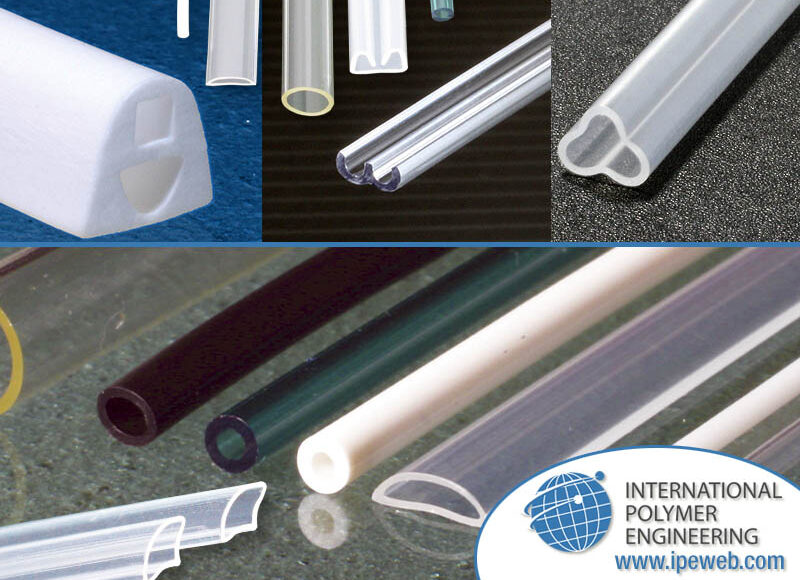

With over 100 mixed years of experience in plastic extrusion, GSH Industries is a leading B2B vendor of custom-made plastic extrusions, tubing, and plastic profiles in North Ohio. Our developers and engineers can aid you in choosing the very best products for your line of product - https://www.ewebmarks.com/author/k3ll3rpl4st8/. We have a vast choice of plastic resins and also can match any type of customized shades to your client's specifications - plastic extrusion profiles.It is just one of the most popular means plastic parts are presently produced as a result of its versatility. Personalized extrusions can be developed into complex shapes of varying densities, strengths, sizes, shades, and even appearances, as well as are reasonably easy to collaborate with. The extrusions can also be developed with performance boosting qualities such as fire resistance, boosted toughness, improved stamina, anti-friction or anti-static homes, and also far more.

It can likewise possibly lead to longer cooling time with will certainly increase your general manufacturing time as well as expenses. Sharp edges as well as notches create powerlessness in the account where splitting or failing can occur considering that they decrease the impact resistance of the profile by creating a high stress focus. If possible, when creating your account extrusion sharp edges need to be prevented all with each other rather aim for rounded edges.

The smart Trick of Plastic Extruded Profiles That Nobody is Discussing

Preferably the distance ought to be equal to the wall thickness of the extrusion. This adds to smoother product circulation during Find Out More extrusion and less stress and anxiety on the profile's corners. They need added adjustments to the die to make certain proper material circulation, can create irregular cooling, and also can create locations of weakness that might result in failure.If your part needs to have hollows, a hollow within an additional hollow is never ever an excellent idea. It will be required out of shape prior to the extrusion solidifies - https://codepen.io/k3ll3rpl4st8/pen/gOKMgmM. If your extrusion needs features such as legs, grooves, snap-ins, or other things inside of the extrusion it is best to create an easily available opening right into the extrusion to make sure that you can better include those functions.

Facts About Custom Plastic Profiles Uncovered

Recognizing some consumers might be not familiar with our plastic profile extrusion abilities, we have actually compiled a list of concerns we are regularly asked. Durometer is a measurement of the material's firmness as well as is determined with a gadget which is pressed against the profile's surface area, resulting in a dial guage reading.

Common ranges are Coast A for flexible materials as well as Shore D for stiff compounds. Twin durometer, or co-extrusion, is the blend of two or more products of differing physical buildings right into a solitary extruded item. An example would certainly be a rigid get rid of adaptable fingers that can be used as a gasket or cushion.

Depending on the part complexity and raw products, one can estimate the costs beginning at much less than $1,000. Due to differing set-up costs and run effectiveness, we attempt to restrict the minimum production amount to 1,000 lineal feet.

The Definitive Guide for Custom Plastic Extrusion Manufacturers

What causes the line. If you take a close consider an attracting for a plastic account with an intersection leg, you will see there is even more mass in the location of the intersection. Because thermoplastic materials diminish some throughout the cooling process, the junction of two legs cools down at a slower price than the rest of the account, causing it to diminish even more due to the mass of the account.

A tool designer would usually divide the flow of both legs within the die, and also enable them ahead back together as the extrudate is being pressed to the front of the extrusion die. This can in many cases create a weld line where the two melt streams are brought back with each other so careful tuning of the extrusion tooling is crucial to lessen this line.

Report this wiki page